Remote management/automation functions tailored to all stages of water purification

Telemetry plays different roles depending on the installation’s size and type:

Small water treatment plant:

The treatment process is very simple, consisting of filtration and disinfection. The SOFREL Remote Terminal Unit directly manages key information (on/off states, pump malfunctions, chlorine levels). It can also perform automation tasks, such as controlling pumping based on the water level in the reservoir supplied by the station.

Large treatment water plant:

The drinking water treatment process is more complex, and the SOFREL RTU is usually connected to a PLC or a network of controllers. This is particularly true in large drinking water production plants that extract significant amounts of water from rivers or lakes for treatment. These complex facilities are typically divided into functional units, each responsible for different treatment stages: screening, coagulation, flocculation, decantation, filtration, ozonation, refinement (activated carbon), and finally, water disinfection.

Thanks to its communication functions, the SOFREL RTU collects essential process data via the PLC, enabling remote operation of the station. When the operator connects to the SOFREL RTU, they input management instructions for the installations, which the RTU then transmits to the PLC. These instructions can also come from other sites communicating with the station (Intersite function). PLCs and telemetry equipment thus work in a complementary manner.

Remote control of the treatment plant by the reservoirs

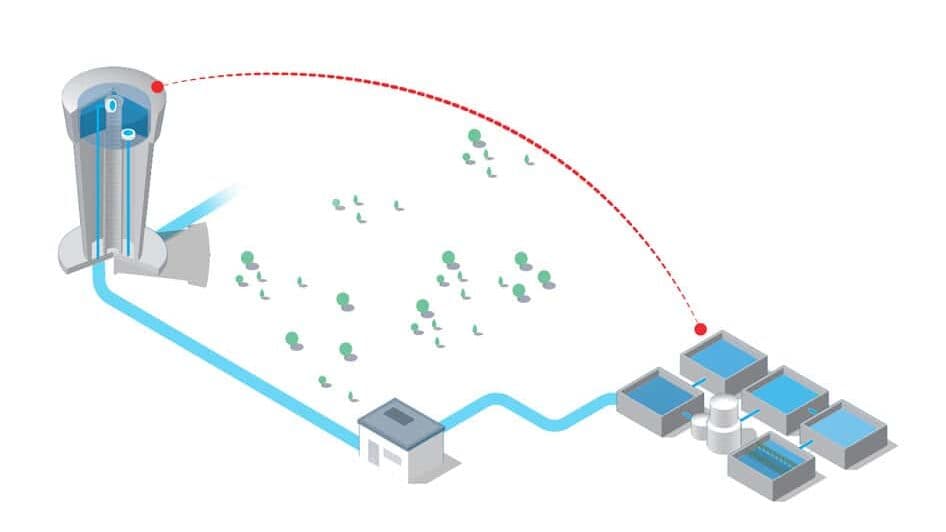

The intersite communication function enables multiple devices to communicate remotely via M2M.

• Local “master” stations located in reservoirs send pumping instructions to the water treatment station/plant when the water level in the reservoirs is low.

• Upon receiving the instructions, the telemetry equipment will either activate the pumping or, if it is connected to a PLC, it will send a request to the controller to start the pumping.

• Depending on how much water is left and what the analysis says about future consumption, it is possible to delay pumping so that it is performed during the off-peak hours for electricity.

Adopt our SOFREL RTUs for optimized and secure management of your drinking water treatment plants

Telemetry solutions monitor potable water treatment processes 24/7, optimizing the operation of water treatment plants. Remote monitoring, process automation, and intelligent resource management ensure efficiency and cost reduction.