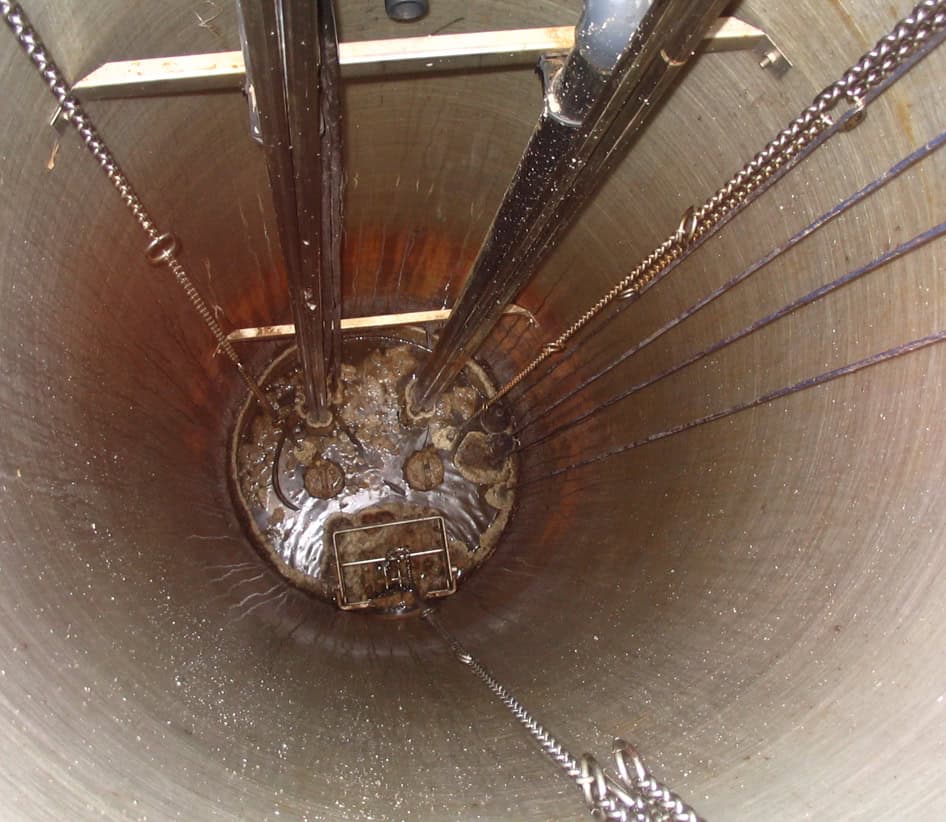

Monitoring lifting stations

Through continuous analysis of tank water level and pump operation, the remote terminal unit performs a set of calculations concerning volumes and flowrates passing through the facility: incoming flow, pump flow, volume pumped by the station, day/night ratio, etc.

Pump flowrates are calculated using a self-adaptive method tried and tested in the field. Operators can therefore anticipate issues of pump clogging or wear and make use of this tool for preventive maintenance. Tracking the day/night rate enables evaluation of parasitic water infiltration into the network.

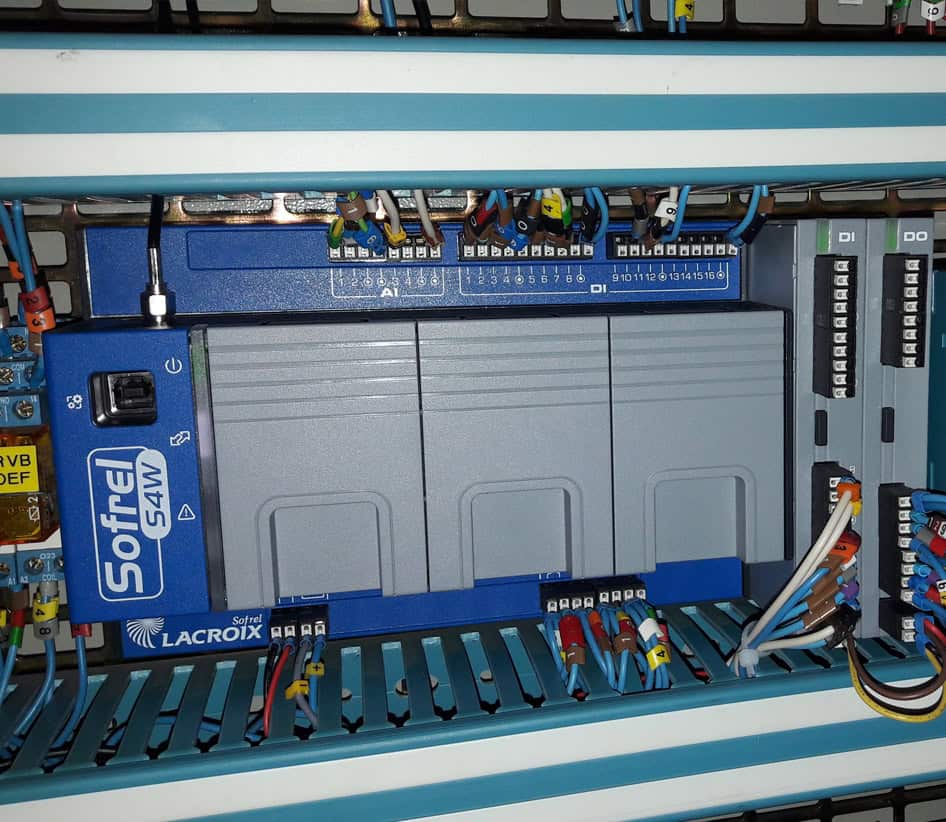

Pumping process control

Effective pump management requires more than simple pump permutation on each start-up. In reality, there are a significant number of criteria to be considered: the number of pumps authorised to operate in parallel, the maximum running time for each pump, the time between a stoppage and start-up, pump and sensor fault management, etc.

All these parameters are clearly accessible in the remote terminal unit settings and are therefore easily adaptable to each specific case or type of lifting station.

Additional functions such as excess flow management enable operators to reconcile the demands of service continuity and compliance with the hydraulic constraints of the network. As such, the remote terminal unit can provide full process control for the lifting station and facilitate greater energy efficiency.

Discover our solutions for lift station management

Lift stations play a crucial role in the collection and transfer of effluents. With SOFREL RTUs, pumping management is optimized, providing precise monitoring of volumes, flows, and pump performance. These solutions also allow for the anticipation of clogging and wear issues, while facilitating preventive maintenance. Discover our solutions for optimized lift station management.